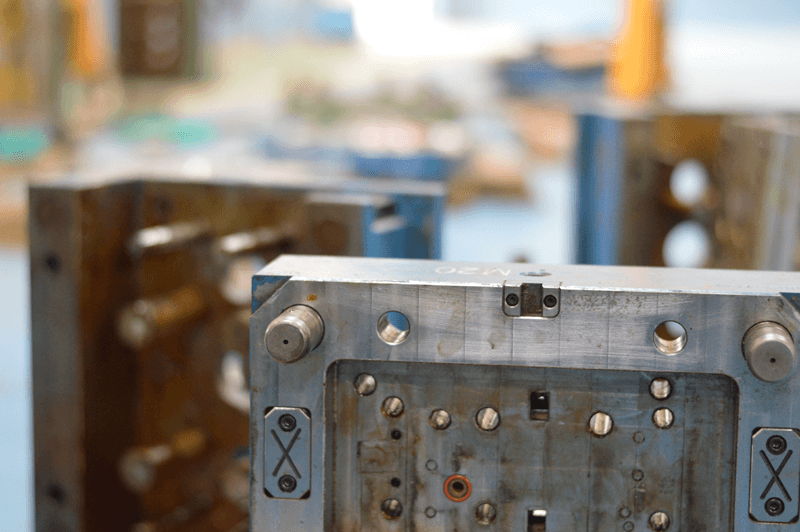

Tool Maintenance is required for all molds at a certain intervals in order to maintain the product quality and size stability of plastic parts. This usually happens due to wearing out of mold components. A well-maintained mold is key to producing consistent, high-quality injection molded parts.

Advantages of having a regular tool maintenance.

Tool repair is required when something breaks/damaged that can create a product outside of specifications or quality standards. As having an advantage of tool room and production at a same place, our engineers can make necessary repairs to put them back in production.

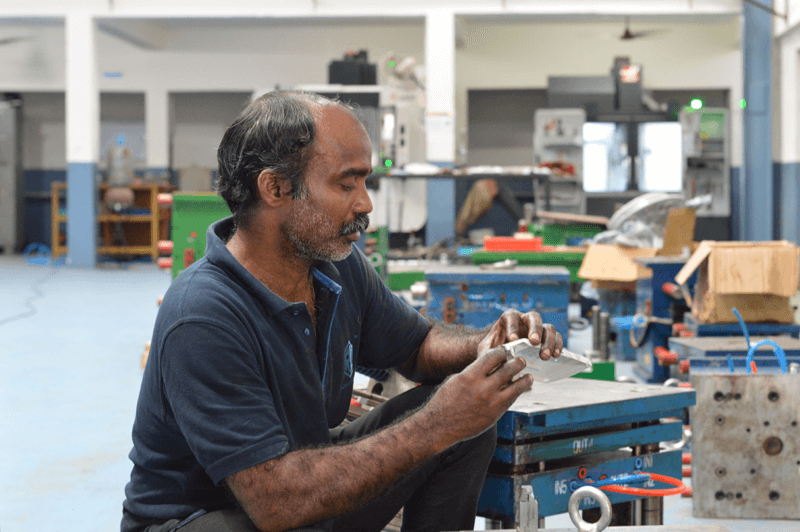

When it comes to Repair or Preventive maintenance, we have an separate team for these. We do preventive maintenance, which includes full mold teardown and cleaning, as well as repairs that fix any damage and restore your mold.

With inhouse machines ranging from conventional milling to advanced CNC and ZNC, we offer a quick turnaround for mold repair and maintenance for mold of any size. We have experience working on domestic and foreign Molds.

© 2024 Radiant Design. All Rights Reserved.Developed by Innov Touch Technologies Pvt Ltd