When a design needs validation with the production grade materials to test the form and fit of components with small quantities, a proto mold tool will be required. Prototype molds will ultimately appear as the bridge between your prototyping and mass production stages. This method was specially designed to economically and quickly produce samples, prototypes, and small series.

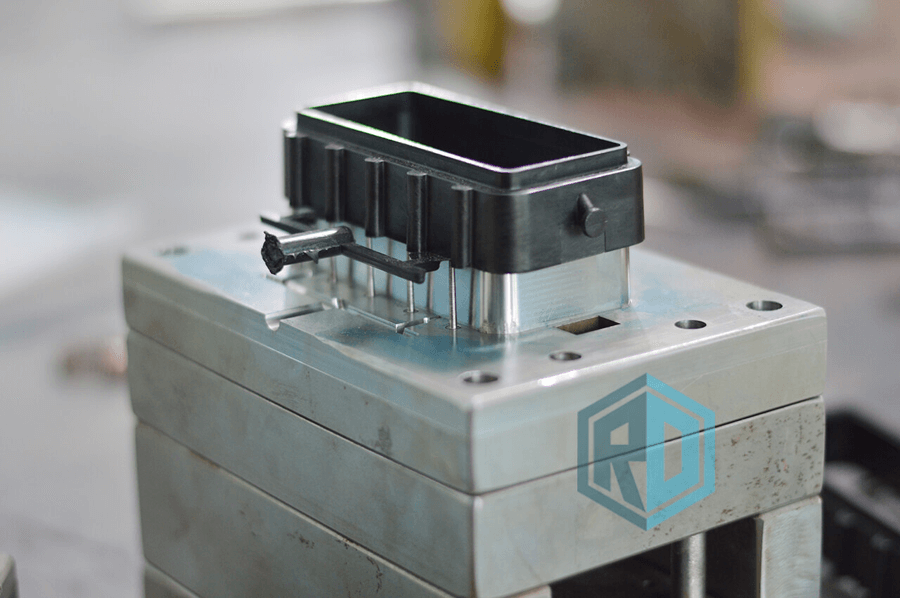

These molds looks like a miniature of the injection mold tools, generally with only the core and cavity part. They are generally machined with soft steel alloy or hard steel depending upon the application.

Mold Cost:

As most of the elements is eliminated in this type of tooling, the mold development cost will be lower than on-demand manufacturing tool.

Lead Time:

These tools will generally take less time to develop. The usual lead time differs between 2-3 weeks.

Market Testing:

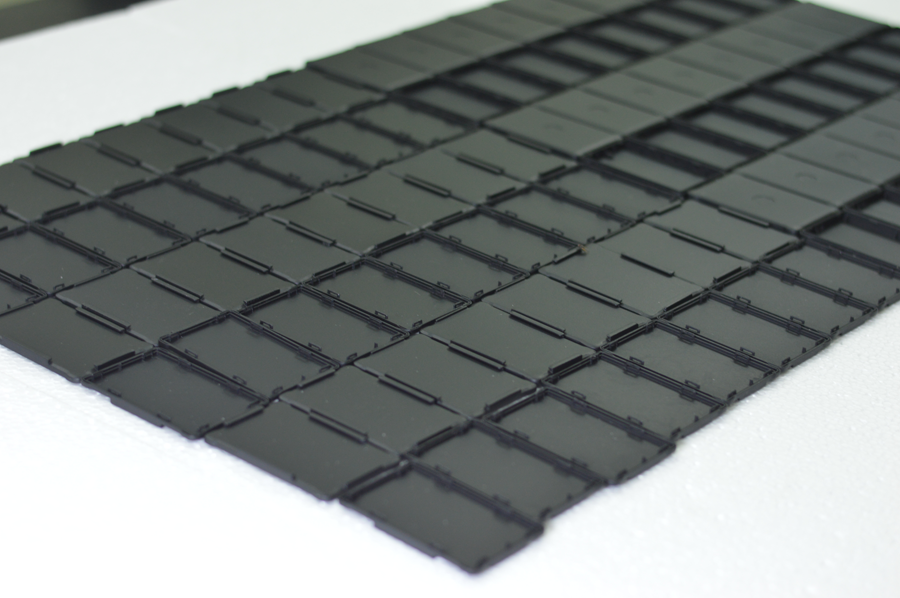

To validate market interest before launching a product, proto mold tools help in producing a pilot run injection-molded part. This will reduce the financial risk.

Wide Choice:

The parts injected will be equivalent to injection molded parts. With this method, a wide variety of materials and finishes will be available.

© 2024 Radiant Design. All Rights Reserved.Developed by Innov Touch Technologies Pvt Ltd